Tuesday, 28 April 2015

Late Night Flurry

I have 2 nights to work on Libby due to being away for the weekend and various other family commitments this week, so tonight Bradley and I got cracking. The prop is back, rebuilt and longer so whilst brad was underneath fitting that, I sorted and fitted the gearlever.

Back under the bonnet, put in the longer feeds for the headlight relays (yet to be connected) and finished off the plumbing under the bonnet. After looking under the bonnet of Andy's car on Sunday at the Register Board Meeting, I found where the missing pipes went and also discovered why the chokes wouldn't work properly (cable in wrong side) so that was sorted. Under the bonnet is now ready.

I placed the air filters on to make sure all the pipework cleared it, and maybe to see what it would look like!

After Brad had done the prop, we started on the exhausts. I've had some lengthening pipes made up so we can temporarily fit the exhausts, these now need cutting to size but that will have to wait as it was too late to be angle grinding at this point. This will make the exhaust 'functional' if not pretty. Once the car is running and MOT'd it will go to a custom exhaust builder to have the system properly fettled and extended and made to fit properly.

Sometime, you just need to keep the end goal in sight..............

I also have found the interior light wiring ready to fit those, and fitted the new wiper cover (bit of chrome, lovely!!). don't worry, the fuel line needs a clean and a new piece of joining hose. That will be done.

Thursday night will be cut and fit the exhaust pieces, plumb in the fuel tank, change this bit of hose above, fit the interior lights............. and then wait until its time to fill with fluids, check the wiring and then turn the key. The plan is, this will happen in the next week. I can't tell you how excited I am getting, it will be the first time this car has run since 1979.....................

Sunday, 19 April 2015

Finishing straight................?

First job of the day, trial fit the propshaft and measure how much needs adding. Using a Stag Prop as a start, we fitted the rear to the diff flange, then measured the gap between the end and the gearbox. Two measurements are needed as a Stag prop has a sliding spline. 120mm extended, 160mm compressed, so I shall be discussing the best way forward with my propshaft builder, but guessing we will be aiming for a mid point of 140mm. I shall also have the UJ's rebuilt and the whole thing balanced and done properly.

Next job was to remove the pipework and carbs I fitted last time as I had managed to fit them back to front! With the carbs facing the right way, everything fitted much better and before long all the fuel lines, overflows and breathers were all installed.

Next the new clutch master cylinder was fitted and connected to the pedal box. Whilst I was buried under the dash I also fitted the new speedo cable. Had two choices, 2000 or Stag. Tried the 2000 one first, too short. Stag one just right, but does seem to foul the gearbox crossmember. No way of changing that but I need to keep an eye on that.

Then under the car and fit the clutch slave, other end of the speedo, then bled the clutch. Nice positive feeling pedal. I then wired up the starter motor, and added in the extra feeds for the relays for the headlights. I chose to take the power feed for this off the back of the starter as it just by where the relays are mounted. Made up the wiring harness and fitted that too.

Next job, refitted the orginal Maserati Air Horns (after Bradley has cleaned them though........ polisher!) I could then fit the overflow bottle and finish the water connections.

We then carried on and fitted all the coolant hoses. Mild panic as I couldn't find the stainless steel water pipe, but discovered it lurking on a shelf...........!

Brad declared that part of the work as "ok".

It really is starting to look complete!

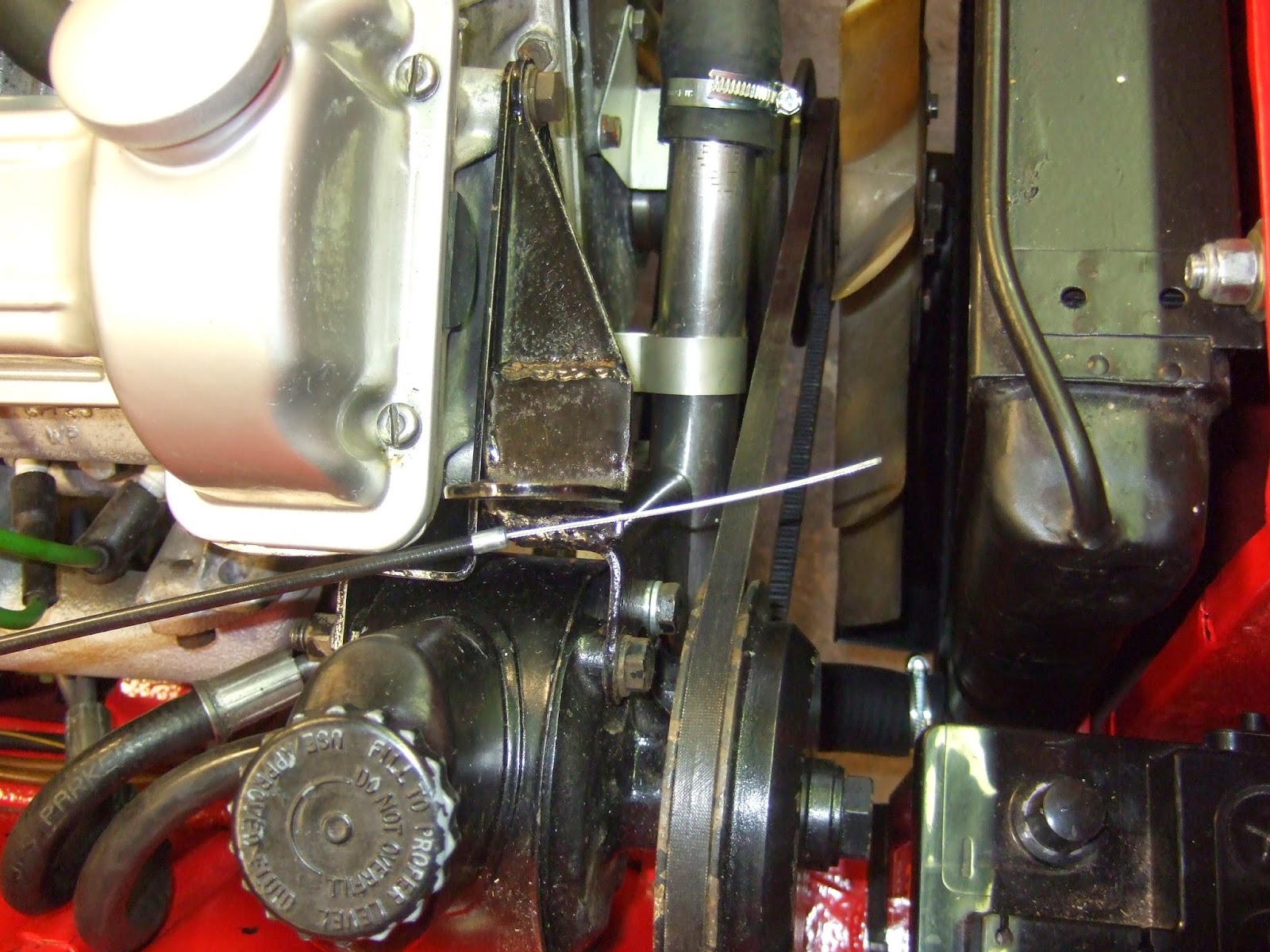

We then fitted the exhaust front pipes and tried to work out how the rest of the exhaust should work. As you can see from this picture, the offside front pipe is sitting too high so will need some "modifying". After lots of head scratching we have concluded that we can cobble something together that will work, but really it is going to need the attention of a proper custom exhaust place to modify it properly to fit.

Whilst under the car I noticed that the bottom water pipe was hitting the alternator fan. What is needed is a clip to hold the stainless pipe in the right place. A quick rummage through my dwindling pile of parts revealed a familiar looking clip with a label on the bag "bottom hose clip". That'll be it then! Removed and refitted the pipe with the clip and all is well.

Finished off by re doing the wiring to the tailgate, made up the missing heated rear window loom and fettled a few things under the bonnet.

Next jobs, fit the prop, try and fit the exhaust as best we can, cut down and fit the battery clamp, after that and some minor trim work to do inside......... its ready to fire.

Next job was to remove the pipework and carbs I fitted last time as I had managed to fit them back to front! With the carbs facing the right way, everything fitted much better and before long all the fuel lines, overflows and breathers were all installed.

Next the new clutch master cylinder was fitted and connected to the pedal box. Whilst I was buried under the dash I also fitted the new speedo cable. Had two choices, 2000 or Stag. Tried the 2000 one first, too short. Stag one just right, but does seem to foul the gearbox crossmember. No way of changing that but I need to keep an eye on that.

Then under the car and fit the clutch slave, other end of the speedo, then bled the clutch. Nice positive feeling pedal. I then wired up the starter motor, and added in the extra feeds for the relays for the headlights. I chose to take the power feed for this off the back of the starter as it just by where the relays are mounted. Made up the wiring harness and fitted that too.

Next job, refitted the orginal Maserati Air Horns (after Bradley has cleaned them though........ polisher!) I could then fit the overflow bottle and finish the water connections.

We then carried on and fitted all the coolant hoses. Mild panic as I couldn't find the stainless steel water pipe, but discovered it lurking on a shelf...........!

Brad declared that part of the work as "ok".

It really is starting to look complete!

We then fitted the exhaust front pipes and tried to work out how the rest of the exhaust should work. As you can see from this picture, the offside front pipe is sitting too high so will need some "modifying". After lots of head scratching we have concluded that we can cobble something together that will work, but really it is going to need the attention of a proper custom exhaust place to modify it properly to fit.

Whilst under the car I noticed that the bottom water pipe was hitting the alternator fan. What is needed is a clip to hold the stainless pipe in the right place. A quick rummage through my dwindling pile of parts revealed a familiar looking clip with a label on the bag "bottom hose clip". That'll be it then! Removed and refitted the pipe with the clip and all is well.

Finished off by re doing the wiring to the tailgate, made up the missing heated rear window loom and fettled a few things under the bonnet.

Next jobs, fit the prop, try and fit the exhaust as best we can, cut down and fit the battery clamp, after that and some minor trim work to do inside......... its ready to fire.

Subscribe to:

Posts (Atom)

.jpeg)

.jpeg)